Manufacture of Automotive Glazing

We offer full systems that integrate multiple functions in one piece of glazing through patented technologies and partnerships with external specialists. For this we are transforming flat glass in shaped glazing using in-house technologies that we carefully developed with internal Saint-Gobain partners.

We have a worldwide up-scaling capability of offering the right technology at the right place to ensure full customer satisfaction.

All our technological developments are conducted with a carbon-neutral and zero non-valorized waste mindset.

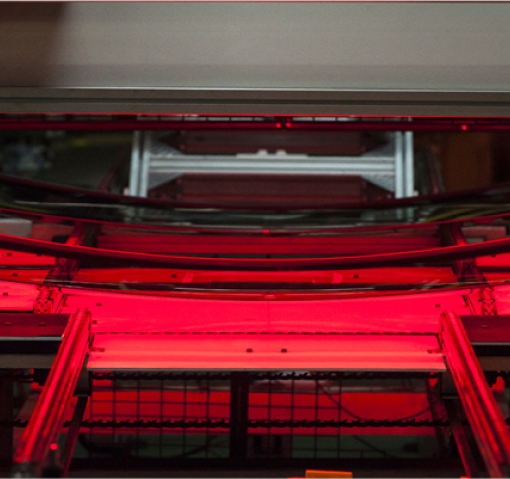

Tempered Glazing

The "Securit" tempering process was discovered in Saint-Gobain's laboratories in 1929, in the course of research undertaken at the request of the automobile industry.

The process consists of strengthening the glass by very fast blast cooling (from 600 to 300° C in a few seconds) and is used to make automotive, building, and specialty flat glass.

Raw glass can be clear or tinted in various shades.

Laminated Glazing

In 1909, the French chemist Edouard Benedictus, invented laminated glass.

The process bonds two sheets of glass using a sheet of transparent plastic interlayer, producing a safety glass. If the glass is broken by an impact, the plastic interlayer retains the fragments and the glass cracks in the shape of a spider's web.

To learn more

Navigate through our glossary page and learn a thing or two about glazing for automotive.